.png?width=300&name=mediamodifier_image%20(30).png)

MYOB Advanced Cloud ERP for Manufacturing Management

Complete Cloud ERP for Manufacturing Businesses

MYOB Advanced Manufacturing is a cloud Enterprise Resource Planning (ERP) system that connects every part of your business end-to-end to support business growth. Integrate production planning and the shop floor with financial management to CRM to inventory management and sales orders to provide real-time coordination across your entire business. Combined with MYOB Advanced Payroll you can have centralised payroll and workforce management with ERP on a single cloud platform.

Growth Friendly Licensing

MYOB Advanced is designed to take care of everything you need both now and in the future. Inventory management, streamlined sales and purchasing, accounting and more – all in a scalable platform.

MYOB Advanced will eliminate hardware costs, giving you a fully customisable platform for a convenient monthly price. Your online data is securely stored, giving you the flexibility and freedom to work the way you want.

Manufacturing Management Features

MYOB Advanced Manufacturing Software integrates manufacturing, inventory management and accounting to help manufacturing businesses ensure raw materials are available for production, efficiently manage the manufacturing process, maintain revisions, and track the financials. Be able to streamline business processes, generate accurate pricing, and calculate your total manufacturing costs.

- Financial Management

- Inventory, Orders & Distribution

- Customer Management

- Project Accounting

- Estimating

- Product Configurator

- Bill of Materials & Routing

- Production Management

- Material Requirements Planning (MRP)

- Advanced Planning & Scheduling Board

- Manufacturing Data Collection

- Engineering Change Control

- Service Management

- Mobile Applications

- Reporting

- Payroll

Financial Management

Full suite of financial and budgeting features and reporting including general ledger, support for multi-currency and multi-company, fixed asset management and managing and understanding your cash position with cash flow forecasting and reporting.

Features within Financial Management include:

• General Ledger

• Accounts Receivable

• Accounts Payable

• Cash Management

• Currency Management

• Bank Feeds.

Inventory, Orders & Distribution

Maintain detailed information on your inventory including supplier codes, barcodes, and cost and sell pricing history. Track inventory levels and costs across multiple warehouses and locations.

Features within Inventory and Distribution Management include:

• Replenishment

• Location Management

• Sub-Items and Matrix Items

• Physical Inventory

• Pricing, discounts and promotions

• Shipping

• Kitting and Disassembly.

Customer Management

Integrated Customer Relation Management (CRM) system for managing leads, contacts, opportunities, and customer accounts.

Features within Customer Management include:

• Sales automation

• Integrated marketing

• Service and support automation

• Customer self-service portal.

Visit our Customer Management Page for Demonstrations

Project Accounting

Manage budgeting, inventory, change orders, timesheets, billing, profitability, and reporting for individual business initiatives. Projects are included in company-wide financial reports with full multi-currency support.

Features within Project Accounting include:

• Project cost tracking

• Advanced billing

• Time management

• Advanced expense management.

Estimating

Prepare estimates for existing or custom items. Create a simple, quick summary estimate or a detailed estimate using a bill of material structure.

Product Configurator

Create a new configured order by simply copying or modifying an existing configured order or quote. A multi-level, dimensional, rules-based system with non-hierarchical feature selections and configuration evaluation. Use on quotes, sales orders, and/or production orders with real-time price and cost rollup.

Bill of Materials & Routing

Connect materials, work instructions and overhead costs to an operation to accommodate the time-phased release of materials. Efficiently plan and manage inventories, costs, and manufacturing processes as well as full revision control. See both engineering and financial views of product structure in the multi-level Bill of Materials software (BOM)/Routing.

Production Management

Use manufacturing operations management software to capture total manufacturing costs, including material, labour, machine, tool, overhead, and outside processes. Manage production orders, release and schedule orders for the shop floor, and track material and labour costs. Compare standard and planned production costs to the actual costs of the production order.

Material Requirements Planning (MRP)

View all supply and demand. Create production and purchase orders directly from the planning screen. Generate time-phased manufacturing and purchasing plans for optimal inventory availability tied to forecast and customer demands.

Advanced Planning & Scheduling Board

Meet customer demands by setting accurate and reliable delivery dates based on the availability of resources.

Manufacturing Data Collection

Print barcodes and utilise scanners to capture data from the shop floor including labour and material transactions and inventory movement.

Engineering Change Control

Manage version control and updates to bills of material (BOM) and routings while controlling effectivity dates that impact material planning, costing, and scheduling.

Service Management

Maximise dispatching by scheduling the right people at the right time and obtain real-time data for work taking place in the field.

Mobile Applications

Capture time, expenses, project issues, change requests and more. Productivity will increase making your construction projects run even smoother.

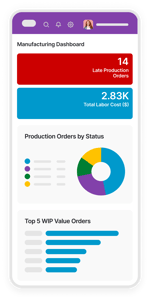

Access MYOB Advanced anywhere, at any time, with easy access via a web browser, or use the MYOB Advanced app for iOS or Android.

SEE THE MYOB MOBILE APPLICATION IN ACTION

Reporting

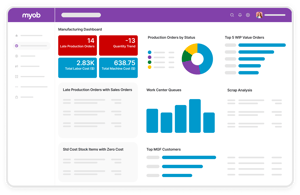

MYOB Advanced provides powerful reporting capabilities specifically designed for the manufacturing industry. With comprehensive and customisable manufacturing reports, you can gain greater visibility into your manufacturing processes and track key metrics such as production efficiency, inventory levels, and more. These reports are fully integrated with MYOB Advanced, meaning you can access real-time data and make informed decisions based on accurate information. With MYOB Advanced manufacturing reporting, you can optimize your manufacturing operations and drive greater profitability for your business.

Payroll

Looking to streamline your manufacturing processes and improve your reporting capabilities?

Contact us today to learn how MYOB Advanced can help your manufacturing business succeed. Our experts provide tailored solutions that meet your unique needs, keeping you ahead of the curve. Take your operations to the next level with MYOB Advanced.